FOR YOUR VEHICLE

From Asbestos to Ceramic: The Evolution History of Brake Pad Mat

Tags: Ceramic brake pads, metallic brake pads, brake pad material development, brake system technology, automotive safety components

When you hear recommendations for brake pad replacement, have you ever been confused by terms like "ceramic," "semi-metallic," or "NAO"? Behind these names lies a miniature evolution history of automotive safety technology. Each material innovation in brake pads, from harmful asbestos to today's high-performance ceramic composites, has aimed to make you stop more safely and reliably. Understanding this history not only helps you understand why ceramic brake pads come with a hefty price tag but also enables you to cut through marketing hype to make truly明智 (wise) choices.

1. Brake Pads: The Engineering Core Behind Safe Stopping

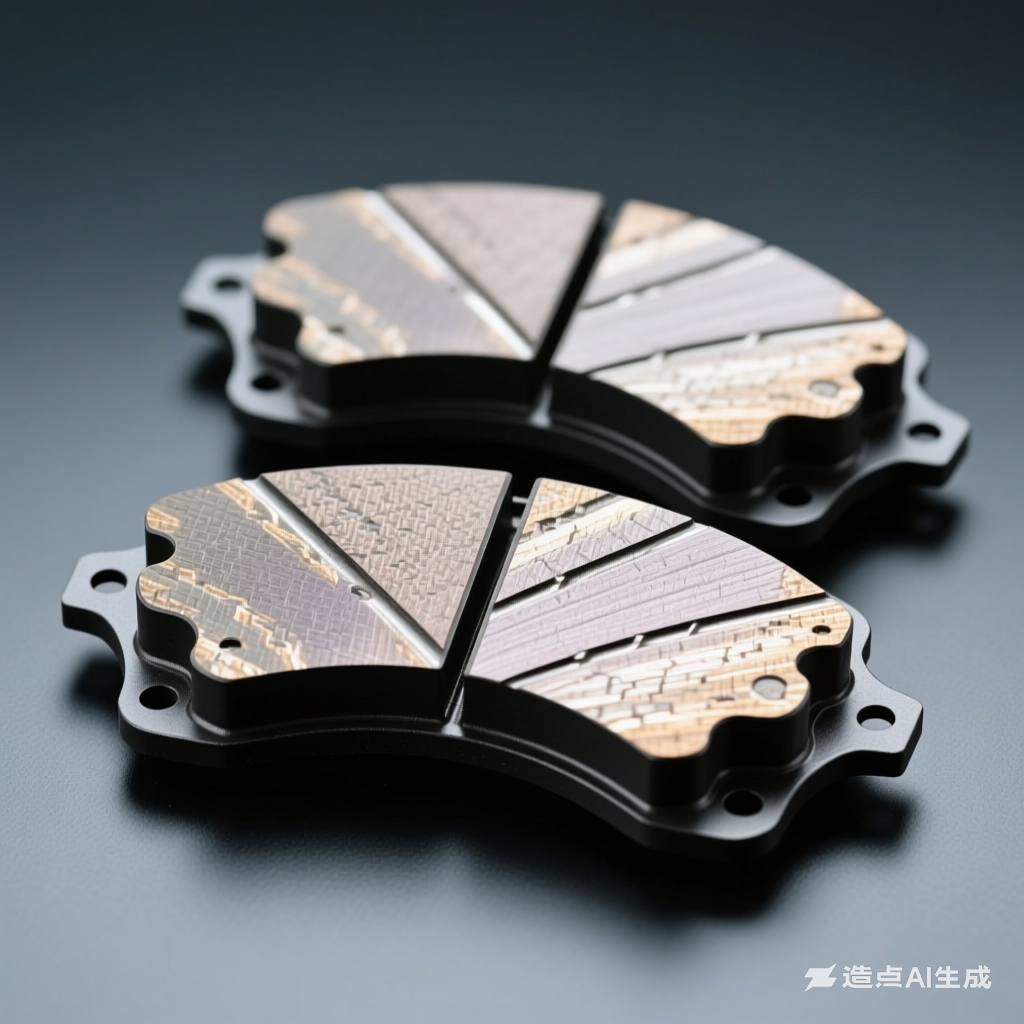

To safely and smoothly stop a high-speed vehicle, there's a precision hydraulic brake system behind it. When you press the brake pedal, force is transmitted through brake fluid to the calipers, pushing the brake pads to tightly "grip" the brake rotor that rotates with the wheel. The enormous friction force converts the vehicle's kinetic energy into heat energy for dissipation, achieving deceleration.

In this process, that unremarkable friction material on the brake pads bears the highest pressure and temperature. It must maintain stable friction coefficients under extreme conditions, not wear too quickly, or fail due to high temperatures. The quality of its material directly determines braking effectiveness, noise levels, dust production, and the entire system's lifespan. Therefore, the evolution of brake pad materials has always centered around improving performance, durability, and safety.

2. The Eliminated Beginning: The Asbestos Era and Rise of Organic Materials

For most of the 20th century, asbestos was the mainstream material for brake pads due to its excellent high-temperature resistance and friction properties. However, its fatal flaw was subsequently exposed: asbestos fibers produce dust during wear that, when inhaled by humans, causes serious lung diseases and even cancer. Based on health and safety considerations, asbestos brake pads have been banned globally.

Replacing them are NAO-type brake pads. "NAO" here refers to "Non-Asbestos Organic配方 (formulation)." It completely abandons asbestos, instead using glass fibers, aramid fibers, rubber, resin, and other organic materials in composite form, possibly with small amounts of metal. The core advantage of this formulation is providing very smooth, quiet braking feel with minimal dust production and less wear on brake rotors. It was once widely used in mid-to-high-end vehicles, meeting people's demand for comfort, but had shortcomings in anti-fade capability under extreme high temperatures.

3. Performance and Compromise: Widespread Application of Semi-Metallic Brake Pads

In pursuit of better high-temperature performance, especially for intense driving and heavy-load conditions, semi-metallic brake pads became one of the mainstream solutions. Their friction materials contain高达 (as high as) 30%-65% metal fibers, such as steel, copper, and iron.

High metal content brings two core advantages: first, excellent thermal conductivity, which quickly dissipates friction heat, preventing heat buildup that could cause brake fluid to boil; second, outstanding anti-fade performance, with less performance degradation during long or high-intensity braking, offering higher reliability. Additionally, manufacturing costs are relatively low.

But these advantages come with significant costs: metal rubbing against brake rotors easily produces high-frequency vibration, leading to louder braking noise; wear generates大量 (large amounts of) black metal dust that easily dirties wheels; the harder metal material also accelerates wear of the brake rotors themselves. Therefore, it's both an OEM choice for many economy cars and a solution in some modification and racing fields pursuing extreme high-temperature performance.

4. The Technology Balance Point: Advantages and Costs of Ceramic Brake Pads

The emergence of ceramic brake pads aimed to find a more perfect balance between the comfort of organic materials and the high-temperature resistance of metal materials. It's not made from daily-use ceramics, but rather formed through complex processes from ceramic fibers, aramid fibers, mineral fibers, and small amounts of copper fiber composites.

It solves several major pain points of the previous two generations: nearly eliminates braking noise; produces minimal dust that is light gray, not dirtying wheels; causes minimal brake rotor wear; while its anti-fade performance approaches or even surpasses semi-metallic pads, achieving new heights in comprehensive performance.

However, the代价 (price) for achieving these advantages is high. Raw material costs are expensive, manufacturing processes are complex (involving high-temperature sintering, etc.), directly导致 (resulting in) several times higher prices than ordinary brake pads. Additionally, in extremely cold environments, its working temperature rises more slowly, and initial braking effectiveness may be slightly weaker. Its expensiveness is the "technological premium" paid for its comprehensive performance, excellent cleanliness, and long-lasting nature.

5. How to Choose: Returning from History to Your Actual Needs

After understanding the development context of brake pad materials, choosing is no longer blind. This isn't a simple proposition of "ceramic is definitely better than metal," but a question of matching needs.

If your driving style is intense, you often drive mountain roads or downhill sections, need extreme high-temperature performance, and can tolerate noise and dust, then high-performance semi-metallic brake pads are the practical choice. If your vehicle is mainly for daily commuting, you strongly pursue quiet, clean driving experience, and are willing to pay higher upfront costs for long-lasting nature and comprehensive brake rotor protection, then ceramic brake pads are undoubtedly the quality-enhancing choice. If your driving style is very gentle, your vehicle is old or budget is extremely limited, then high-quality NAO organic pads can also provide reliable braking protection.

The evolution history of brake pads is a microcosm of the automotive industry's continuous pursuit of safety, comfort, and environmental protection. Each material innovation aims to better solve problems left by predecessors. When replacement is needed, don't blindly worship "ceramic" or "high-end" concepts, but return to essence: examine your driving environment, habits, and budget, choosing the one that best matches your actual driving scenario. After all, the most suitable is the best safety investment. When replacing, please be sure to choose qualified products from legitimate channels and have them installed by professionals to ensure this life-critical component is flawless.